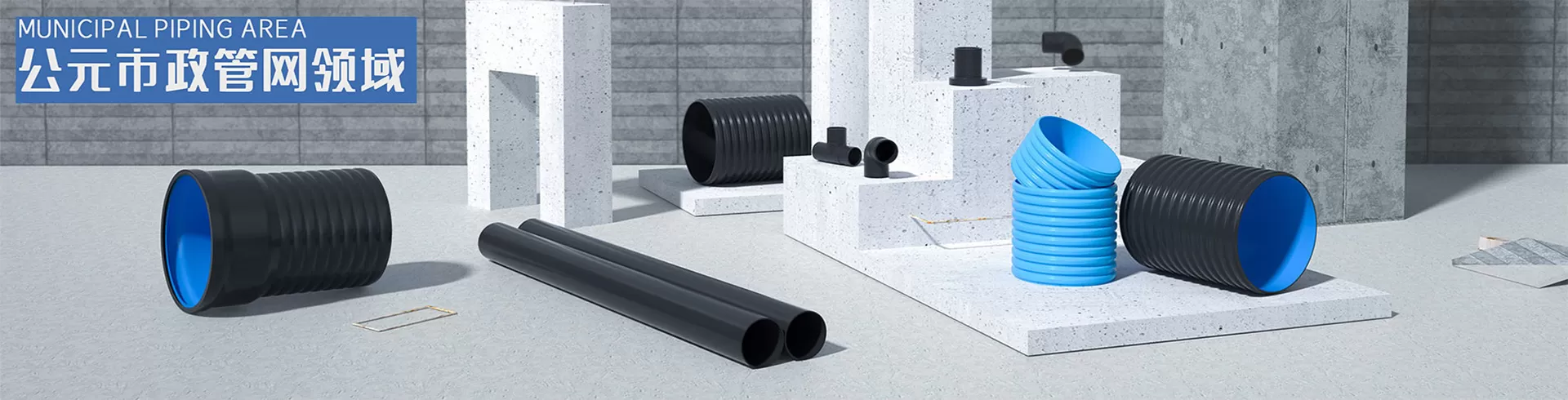

In today's ever-accelerating urbanization process, municipal drainage system is the "blood" of urban operation, and its safety and durability are directly related to people's livelihood and ecological security. Traditional pipes are prone to corrosion, leakage and deformation under complex geological conditions and long-term service environments. The appearance of PE carat pipes is bringing revolutionary changes to the field of municipal pipes through the deep integration of material science and engineering design. The core breakthrough of

PE carat pipes lies in its unique structural design. Through multi-layer co-extrusion technology and winding molding process, the pipes achieve precise regulation of axial and circumferential stiffness while maintaining high toughness. This design allows the pipeline to effectively resist external soil pressure and ground dynamic loads. The ring stiffness can reach SN16 level or above, and it can maintain a stable form even in deep burial or high traffic load areas.

Corrosion resistance is another major technical highlight. The inherent resistance of polyethylene materials to electrochemical corrosion, combined with the application of modified additives, allows the pipe to serve for a long time in a wide range of medium environments with pH values of 2-12, which greatly extends the service life of the pipeline. Compared with the situation where traditional materials require regular maintenance, PE carat pipes truly realize the engineering ideal of "one-time laying, worry-free for life".

The improvement of installation efficiency is also eye-catching. With the use of socket-type electric hot melt connection technology, no large machinery is required for on-site construction. The single interface connection time is shortened to the minute level and fully automated sealing is realized. The measured data shows that the comprehensive construction efficiency of the project using this technology is improved by more than 40%, and the hidden danger of interface leakage is eliminated at the same time.

In terms of environmental performance, the recyclable characteristics of raw materials meet the requirements of circular economy. A closed-loop water supply system is used in the production process, and the energy consumption is reduced by 30% compared with traditional processes. The green manufacturing concept is practiced throughout the process. After third-party testing, the pipes can still be recycled and remanufactured after the end of their service life, and the material utilization rate is over 95%.

At present, this type of pipes has been successfully applied to key projects such as urban comprehensive pipe corridors, rain and sewage diversion transformation, and sponge city construction. In a coastal city underground pipe gallery project, PE carat pipe operated continuously and stably for more than 5 years under the challenging environment of 8 meters deep burial and high groundwater level. The pipe body did not have any deformation or leakage, which fully verified its technical reliability.

With the development of intelligent pipe network system, the new generation of PE carat pipe has begun to integrate the reserved interface of sensing elements, which reserves a technical window for the future realization of intelligent functions such as real-time monitoring of pipe network and network traffic regulation. This advanced design concept once again reflects the leading role of technological innovation in industry standards.

From material innovation to structural optimization, from process breakthrough to application expansion, PE carat pipe is redefining the performance benchmark of municipal pipe with systematic technological innovation. Its comprehensive performance advantages not only solve the pain points of traditional pipe network construction, but also provide reliable infrastructure support for new urbanization construction, and promote the development of municipal engineering in a safer, more durable and smarter direction.

.jpg)