With the acceleration of the urbanization process, the performance requirements of municipal drainage systems for pipes are increasing day by day. Traditional concrete pipes and ordinary plastic pipes are gradually showing limitations in terms of corrosion resistance, installation efficiency and environmental adaptability. PE carat pipe (High Density Polyethylene Winding Reinforced Pipe), as an innovative solution, is becoming a new favorite in the field of municipal drainage with its excellent comprehensive performance.

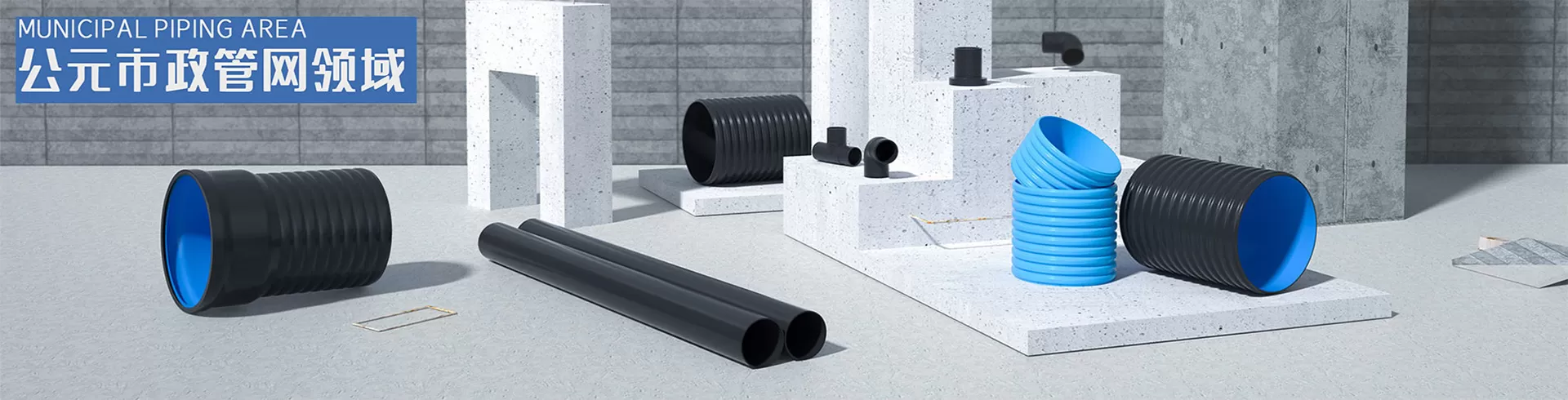

PE carat pipe is made of high density polyethylene (HDPE) as the main raw material through thermal winding molding process. Its most significant feature is its extremely high ring stiffness (up to SN16 or more), which can effectively resist soil load and traffic pressure. It is suitable for engineering scenarios with large buried depths. At the same time, HDPE material endows the pipeline with excellent chemical corrosion resistance, which can cope with the long-term erosion of domestic sewage, industrial wastewater and complex underground environment, and the service life can reach more than 50 years.

Installation convenience is another major advantage of PE carat pipe. The pipeline adopts socket electric fusion connection technology, and no large machinery is required for on-site construction. Only professional hot melt equipment can quickly complete the interface sealing. This connection method not only reduces labor and time costs, but also ensures zero leakage of the interface, fundamentally avoiding the risk of groundwater pollution. In addition, the pipeline is light in weight (about 1/10 of concrete pipe), and the transportation and handling efficiency is significantly improved.

environmental protection properties are highly compatible with modern engineering concepts. PE carat pipe has no pollutant emissions throughout the process, and can be recycled and reused 100%. The smooth design of its inner wall reduces fluid resistance, improves drainage efficiency and reduces the risk of siltation. Compared with traditional pipes, it effectively avoids problems such as brittle cracking of concrete materials and corrosion of steel pipes, and reduces maintenance costs from the source.

At present, PE carat pipes have been widely used in urban rainwater collection systems, sewage trunk pipe networks, industrial park drainage and other fields. Especially in response to extreme weather, its high toughness and anti-deformation foundation ability can effectively prevent pipeline rupture and ensure the stable operation of drainage systems. With the advancement of "sponge city" construction, this kind of pipe with both structural strength and eco-friendly characteristics will become an important support for building sustainable urban infrastructure. In the future, with the continuous optimization of material technology, PE carat pipe is expected to further expand the application scenarios in the fields of intelligent monitoring and prefabricated assembly construction, and provide more efficient drainage solutions for smart city construction.